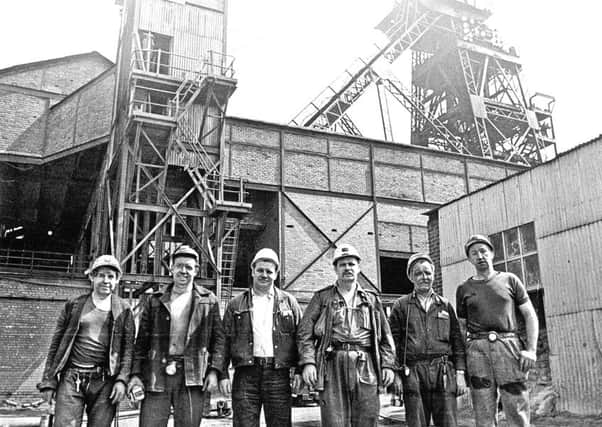

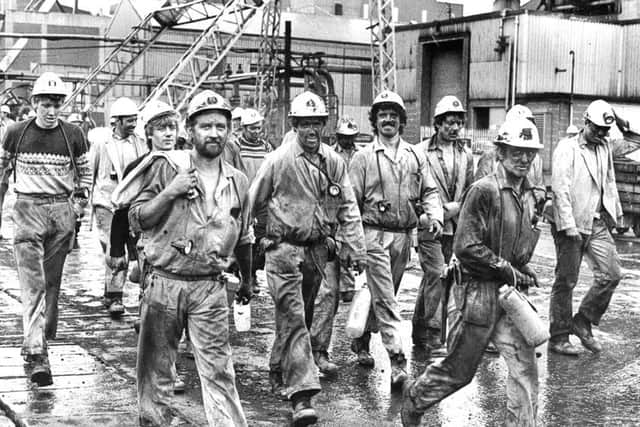

Nostalgia on Tuesday: King coal's demise

The Hatfield Colliery Co. was formed towards the end of 1910, but it was not until October 4, 1911, that the first sod of the new colliery was formally cut.

A small company of directors, officials, mining engineers, with some of the neighbouring people, numbering about 50, assembled in a large field. Shortly after 12.30 pm Thomas Townrow, of Chesterfield, chairman of the directors of the company, stood in the centre of a ring, which marked the spot where number one shaft was to be sunk, and with a small spade he cut the turf in an oblong, and putting his spade beneath it, turned it over.

Advertisement

Hide AdAdvertisement

Hide AdMr Townrow then went to the other shaft site and performed a similar operation. In a short speech he said coal would not be reached before 800 or 900 yards had been sunk. A good many difficulties would have to be contended with, and a good deal of work to be done by the mining engineers. It was the intention of the company to work the Barnsley seam of coal. The contractors’ period of time for sinking the colliery was estimated at two years and nine months.

The Doncaster Chronicle of March 5, 1915, noted that it was impossible to visit Hatfield without being impressed with the changes that were coming over the scene: “Here we have a district, once the happy hunting ground of Kings and Monarchs, now destined to become a centre of coal and commerce. On the spot where royalty once disported themselves, where archers drew the long bow and sent their shafts at the red deer, are now shafts of a very different character, up which the latest machinery will wind coal from the bowels of the earth.”

In March, 1915, it was also announced that work at Hatfield Colliery had been affected a good deal by war. Employment for at least 50 per cent more sinkers could have been found since the war started. At that time 130 sinkers were employed out of a total workforce of 300 men who were working at the pit. The war had meant the withdrawal of a number of men. It had also affected the supply of material.

No 1 shaft at Hatfield reached the Barnsley Bed on August 15, 1916, at a depth of 852 yards. It was completed to a depth of 881 yards on September 11, 1916. No. 2 shaft was completed on April 1, 1917, at a depth of 872 yards. There was a delay of about 12 months in this shaft owing to water difficulties encountered.

Advertisement

Hide AdAdvertisement

Hide AdIn 1927, Hatfield Main was acquired by the Carlton Main Colliery company. At that time, the colliery employed 2,300 men and the daily output was 2,400 tons.

On March 28, 1930, the Yorkshire Evening Post said Hatfield Main was developing quickly and promised to be the biggest pit in the Doncaster coalfield area and the only ‘new’ colliery working two seams simultaneously. It had obtained several foreign orders, and management required 600 more employees. In 1930 there were 3,600 employees, but the management said they could find work for 500 more coal getters and 100 other hands. The weekly output now exceeded 20,000 tons. A big problem was housing, and although Hatfield had built 1,471 houses and Thorne Rural Council nearly 300, there was still need for many more.

There was a Social Section at the colliery which arranged concerts and lectures for the workers. The Workers’ Educational Association was also active.

One man died and over 50 were injured in a cage crash at Hatfield Main Colliery on December 12, 1939. Most suffered fractured limbs – and 10 men and boys needed amputations. A Doncaster jury returned a verdict of accidental death at an inquest, on Friday, March 15, 1940, on Daniel Horrigan, a stoneworker of Arundel Street, Stainforth. The accident was due to overwinding of the cage when the men of the morning shift were being raised to the surface, and men on the afternoon shift were being lowered into the mine. During this winding something went wrong and instead of the descending men being lowered gently, the cage hit the pit bottom with force.

Advertisement

Hide AdAdvertisement

Hide AdIn 1967 the Hatfield and Thorne collieries were merged, becoming separate again in February 1978. They were merged again in February 1986. In November 1993, it was announced the combined pit would close, which took place on December 3 1993, when under ownership of British Coal.

On 4 January 1994, a team from the pit’s management announced they wanted to re-open the pit, forming Hatfield Coal Company Ltd. In its first year of operation the company made a profit of £2.4m. In August 2001 the company went into receivership. The firm employed around 200 people.

In October 2001,Richard Budge, former owner of RJB Mining, took control of the pit,with his company Coalpower. In late 2003, Coalpower went into administration, then liquidation in April 2004.

In 2006 Richard Budge restarted the colliery, via company Powerfuel. The Russian coal company Kuzbassrazrezugol (KRU) acquired a 51 per cent stake in Powerfuel for £36m. Coal production commenced in August 2007 but three years later Powerfuel entered administration.

Between 2011 and closure in mid 2015, Hatfield underwent a number of ownerships that including the employee-controlled company Hatfield Colliery Partnership Ltd.