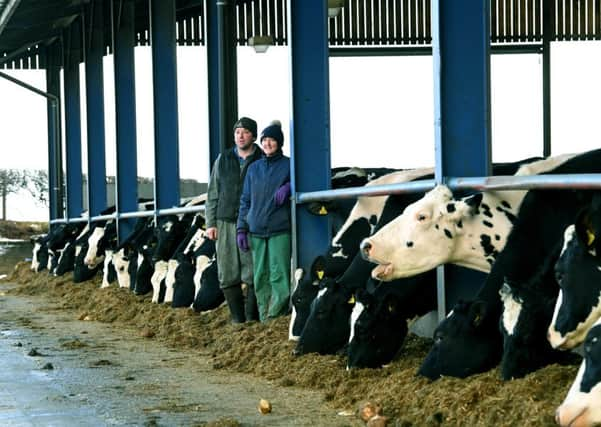

Drive for efficiency at Melmerby farm

“Losing money focuses your mind,” says Andrew Avison of Middlefields Farm, Melmerby near Leyburn who I visited just over a year ago as the price was on its recovery route. “You have to find savings from everywhere and the greatest cost for a dairy farm is feed.”

Andrew is currently fourth in a UK league table produced by Keenan, the diet feed machine specialists, for feed conversion efficiency. Michael French, Keenan regional sales manager, was on farm with Andrew this week explaining how this ranking has been achieved and what it means.

Advertisement

Hide AdAdvertisement

Hide Ad“Feed conversion efficiency is like miles per gallon. There are farmers who are averaging a feed cost of 19p per litre and putting themselves under unnecessary pressure. The lowest cost in the UK by our league table is 10.1ppl and Andrew is at 11.2ppl.”

When dairy farmers were receiving as low as 17ppl for their milk two years ago, feed costs were crippling. Fortunately, Andrew’s latest prices through long-term ally Charlie Payne of Paynes Dairies at Boroughbridge were just over 30ppl for December and just over 29ppl for January.

Andrew is a typically blunt Yorkshire farmer, not one to take kindly to others telling him what to do, but has become a convert to Keenan and their latest technology “We’d had a Keenan 140 diet feeder that had cost us nothing to run as it was so reliable and when I was approached about a new machine with their In Touch technology I reckoned we didn’t need it.

“I looked at other machines but went with the Keenan 360 with the In Touch system. While we have become more efficient and it has been a real team effort there’s no denying the new Keenan and In Touch, in conjunction with everything else we have done, has cost us less in feed, improved herd productivity and saved us having more head of cows milking.”

Advertisement

Hide AdAdvertisement

Hide AdMichael tracks all of his Keenan owners’ results and tells of how Andrew’s have improved since the day he started recording them in 2009. “Andrew’s first results for one kilo of dry matter (feed) was a conversion efficiency of 1.01 litres of milk.

“The idea with In Touch is if you make a slight change it will tell you the cows ate this and produced that. It doesn’t lie.

“Andrew had a new In Touch controller fitted last July. We made a few tweaks and his productivity from one kilo of dry matter is now at 1.51. That’s 50 per cent more milk being produced by the same number of cows.”