Video: Paying fromage to France, it’s Brie from Huddersfield

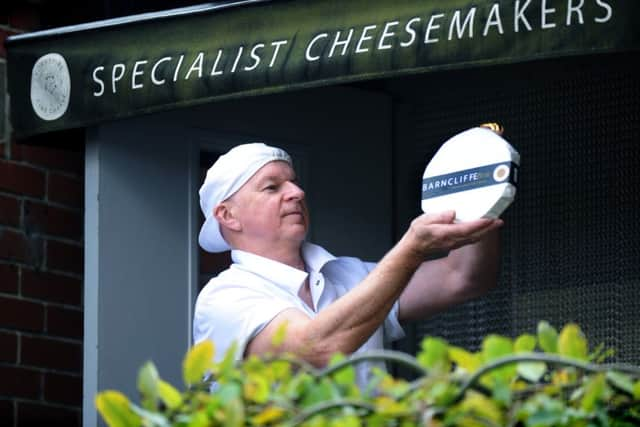

Barncliffe Brie, hand-made by Danny and Carole Lockwood at Shelley, near Huddersfield, is the only Brie made in Yorkshire and is proving increasingly popular in restaurants, delis and farm shops.

Demand is so strong that the couple are working 80-90 hour weeks to keep up with demand.

Advertisement

Hide AdAdvertisement

Hide AdTheir traditionally made Brie has already won two prestigious prizes.

Mr Lockwood collects milk every day from a specialist herd of cattle less than half a mile away from his business at Barncliffe Mill.

He makes every cheese by hand, stirring the milk, cutting the curd and turning the Bries as they set.

Even though it’s a Yorkshire product, there’s a taste of the continent because the milk comes from a herd of 330 pure bred Meuse-Rhine-Issel cattle, renowned across Europe as perfect for cheese-making.

Advertisement

Hide AdAdvertisement

Hide AdMr Lockwood said: “The milk we use is from continental cattle which are specialist cheese-making cattle, and they’re less than half a mile from here.

“They produce extremely good quality, high-fat, high-protein milk and on the continent the bulk of the milk from these cattle goes into cheese making because it helps it coagulate better.”

The story of Barncliffe Brie began four years ago after Mr Lockwood, 59, sold his catering business and began looking for a new direction.

He said: “We had thought about making ice cream, but a lot of people are doing that, so we thought about cheese, which would be something a bit different.”

Advertisement

Hide AdAdvertisement

Hide AdHe knew that his friend, farmer Gordon Dearnley, of Bark House Farm, kept the specialist cattle and approached him.

“Gordon makes ice cream, and then I came along and said, ‘I fancy making cheese’, and he said, ‘I think you’re wrong in the head, it’s too complicated, but I’m quite happy to let you have the milk if you think you know what you’re doing’. So we got the milk supply.”

Mr Lockwood then talked to another friend, cheese wholesaler Michael Lee.

“It was Michael who said, ‘There’s nobody making Brie in Yorkshire’, and the fact that these cattle are from the continent and we’ve got the milk from them was quite a nice tie-up, and it’s a nice story to make Brie in Shelley.”

Advertisement

Hide AdAdvertisement

Hide AdMr Lockwood went on a couple of courses, the second led by a French expert, but there were mistakes before Barncliffe Brie was right.

“It was such a steep learning curve that you wouldn’t believe it,” said Mr Lockwood.

He now produces about 120 kilos of Barncliffe Brie a week.

The milk has to be warmed to a very precise temperature, and cultures introduced to solidify it and enable the ripening process to take place. The work involves a lot of stirring.

The Brie has to be moulded when its acidity level is just right, which is a very narrow window.

Advertisement

Hide AdAdvertisement

Hide AdIt is hand-ladled into moulds, and then each cheese has to be turned three times over the following two hours to create the flat surface on each side and assist with drainage.

The cheeses drain overnight, are removed from the moulds, and then go into a brine bath.

The cheeses go into a ripening room, carefully temperature controlled, for 12 days to allow their distinctive white coating of mould to develop.

It takes another eight weeks for them to ripen - but being patient is certainly paying off.