How RB investment of £105m into Hull is creating jobs and putting the city on the map

For the Reckitt family, these two territories represented its priority for export markets. Given that the prevailing mode of travel at the time was ship, this was a massive ambition. However, within a short period of time, it would be active in these areas.

Step forward to 2020 and the business, formerly known as Reckitt Benckiser, is more of a world player than ever, selling into 200 countries. Yet Hull remains at its core.

Advertisement

Hide AdAdvertisement

Hide AdStep into any pharmacy on the planet and you will be able to buy consumer healthcare products developed and manufactured on RB’s Hull site.

RB is the biggest consumer-goods company in the UK and produces more than 1,000 different products that are developed at the Hull site, among them Nurofen, Lemsip, Disprin, Bonjela, Dettol and E45.

INVESTMENT

Late last year, RB officially opened its new £105m Science and Innovation Centre in the city, and the FTSE100 company’s Hull base is now the largest development centre it operates in the world.

For Dr Bruce Charlesworth, RB’s chief medical officer and site lead for Hull, the new facility represents a game-changer for the business. RB’s headquarters may be in Slough and have a presence in 60 different countries, but the Hull site is, in Dr Charlesworth’s view, the firm’s primary location for its science.

Advertisement

Hide AdAdvertisement

Hide AdRB employs 1,400 people in Hull in total, with 800 in science-based roles. More than 30 nationalities are represented in the workforce of the Hull site. And, as Dr Charlesworth tells Yorkshire Vision he sees this proportion increasing.

“We are attracting people from other RB sites. We are now seen as a place to come and get experience,” he says.

“Now we have these facilities we have become very attractive in terms of the science. Previously we were not a destination for people who wanted to do high science, whereas now we are.”

INTERNATIONAL

As an international business it would have been feasible for RB to have located the facility anywhere in the world and indeed Dr Charlesworth confirms that other destinations were actively considered. But given that Isaac Reckitt founded his starch mill in Hull in 1840, the historical pull of the city was powerful.

Advertisement

Hide AdAdvertisement

Hide AdBut Dr Charlesworth said that there were more factors at work beyond the sentimental.

“Heritage was important,” he says, “but we owned the site, which was a big influencing factor, as was the talent we have got. We have a long-serving workforce. That disruption would have been huge.

“The proximity to factories both here and Nottingham, the cost of land, the cost of labour – a lot of that was weighed up.

“And it was weighed up against other sites. We looked at Singapore, India was considered, some in Europe – and Hull won out on balance. It wasn’t one thing, it was the whole picture.”

Advertisement

Hide AdAdvertisement

Hide AdThe RB facility’s eye-watering price-tag becomes more understandable as you walk around it. It is attached, tastefully, to the older RB building, and linking the two is a grand atrium, dubbed the Innovation Pathway. Designed as a co-working and collaborative zone where all staff can do their work, it includes windows looking in on the state-of-the-art laboratories.

Here, RB provides very much an end-to-end offering for consumer healthcare products found in homes across the world. From developing the products, testing them, refining them and establishing how they can be manufactured to an appropriate scale, every step of the product’s life, from its genesis to being sent out to market, takes place in Hull.

This involves a plethora of cutting-edge machinery and technology which looks at everything from consumer testing to climate control to ensuring that every single medicine produced for a product is produced to the same specification and composition.

“That’s a complex thing,” says Dr Charlesworth. “Making one cake is one thing, but making 10,000 cakes is a very different process.”

IMPACT

Advertisement

Hide AdAdvertisement

Hide AdThen there is the impact on productivity. The new laboratories are not constrained by the layout of the old factory building, nor are teams siloed by department.

The new layout of the labs has cut the number of steps taken on average by a scientist down from 1,900 every two hours to 1,300 steps in three hours. Less time fiddling around adds up to more time on the science and analysis of the products.

And, again, it makes the Hull site more of a pull to the best scientists, Dr Charlesworth claims.

“It will help with attraction and retention of talent,” he says. “From a productivity and innovation standpoint this should help us on that journey to being one step ahead.

Advertisement

Hide AdAdvertisement

Hide Ad“It is a competitive market; you need to be creating new ideas and creating competitive advantage to give consumers what they want but also doing something that is ethically correct. That is a new focus for us.

“Our new CEO is very much talking about our responsibilities. We are doing better science, more science – hopefully keeping consumers safer with even more quality control. Ultimately, what that should mean is growth. Obviously we are about commercial ambition as well.

“But hopefully, commercial success will come as a result in terms of new products, new markets potential new acquisitions.”

The investment forms part of a wider change in direction from RB. Previously the business was primarily known for cleaning and home-hygiene products, with consumer health something that had grown out of that via acquisition. However, healthcare has been selected as the sector that will enjoy increased focus.

Advertisement

Hide AdAdvertisement

Hide Ad“There are a lot of healthcare businesses that dabble in consumer healthcare and the majority of their business is prescriptions,” Dr Charlesworth says. “Whereas we are more of a consumer health business that has grown out of a cleaning and home hygiene business.

"This reaffirms that intent and showcases that. In terms of talent attraction, in terms of the robustness of science, in terms of being science-led – all things a healthcare business needs to be – this has been transformational.”

RB's history in Hull

The Hull base of RB is known to locals in the city as Reckitts. However the wider public, especially those not from Hull, may not be aware of the pivotal role the firm’s Hull base has played in commercial history.

Dettol and Harpic, products used throughout the globe, were both invented in Hull at RB sites.

Advertisement

Hide AdAdvertisement

Hide AdToday, the manufacturing and development of products for the likes of Scholl, Gaviscon, Nurofen, Strepsils, Veet and AirWick, are indelibly linked to Hull.

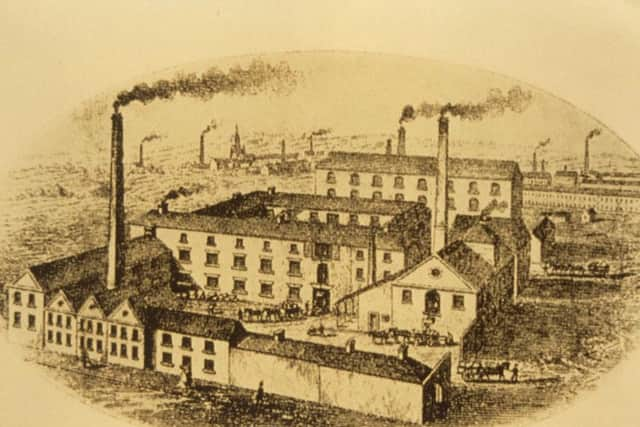

It is all a far cry from the mill that was opened by Isaac Reckitt in 1840. Reckitt & Sons, as it was known then, would provide employment to Thomas Ferens, who joined as a clerk and became chairman.

The Reckitt family and the business constructed hundreds of homes, public facilities and libraries in the city.

Ferens was instrumental in buying the land for the University of Hull and Ferens Art Gallery, while Reckitts directors also bought and gifted East Park to the community and heavily supported Hull Royal Infirmary.

Advertisement

Hide AdAdvertisement

Hide AdThe firm’s massive international growth in the 20th century led to many mergers and acquisitions over the years and the company name changed regularly, most notably in 1999 with the merger of the Dutch-based Benckiser NV household products business. The move brought brands like Vanish, Finish and Calgon to the portfolio of what became Reckitt Benckiser, later shortened to the RB of today.