Rotherham printing giant instantprint launches new £5m book binding division

The Rotherham-based printing giant, which employs hundreds of staff at its factory in Manvers, said that the launch and investment came directly from customer feedback with the aim of making the print buying journey easier.

Instantprint said it is focusing heavily on guaranteed quality from its team of expert book makers with almost six decades of book printing experience.

Advertisement

Hide AdAdvertisement

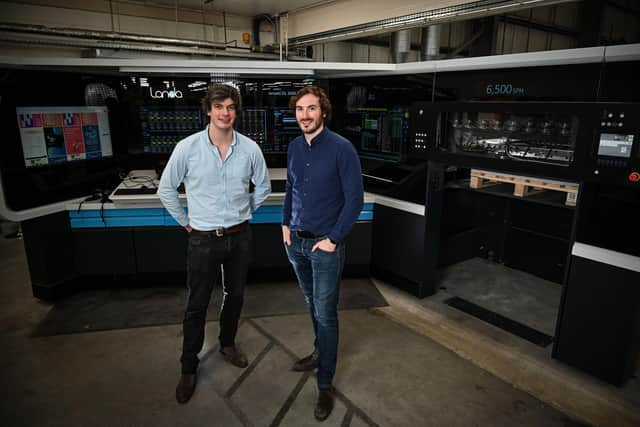

Hide AdInstantprint was the owner of the UK’s first nanographic press. Now a second Landa S10P Nanographic Printing press has been ordered to bolster instantprint’s operations in luxury and lay flat book printing, as well as stitched and perfect bound booklet products – some of the fastest growing segments of the business.

This investment will allow instantprint to improve its growing booklet range.

As part of a broader £5m investment in its book printing division, the new seven-colour Landa S10P will enhance instantprint’s production capacity. The press will be integrated alongside the existing S10P in the instantprint workflow allowing a seamless flow from customer upload and approval through to printed sheets on the floor.According to instantprint, the selection of its second Landa S10P was based on its print quality and economic advantages, which positions it ahead of the competition.

James Kinsella, co-founder of instantprint, said: “The print market is highly competitive and to support our customers with high-quality books that make them look exceptional, we knew we need to invest in our factory to ensure that we can produce books at the highest quality and lowest unit cost.

"The first Landa press has fitted seamlessly into our workflow and has given us a lot more flexibility around what we can offer to our customers.”