Yorkshire university makes thousands of face shields for NHS

This article contains affiliate links. We may earn a small commission on items purchased through this article, but that does not affect our editorial judgement.

A team of engineers from the University of Bradford are working around the clock to mass produce face shields to help fulfil vital NHS orders for PPE.

The work is being carried out at the university's department of engineering in collaboration with two local companies, Leeds-based additive manufacturer ActiveCell Technologies and Teconnex from Keighley.

Advertisement

Hide AdAdvertisement

Hide AdProfessor Tim Gough, head of the department of mechanical and energy systems engineering, from the University of Bradford, said the work started in response to an order for the equipment from the NHS.

He said: "A lot of transmission [of coronavirus] is coming from patient coughing and that can infect the carer through respiratory transmission.

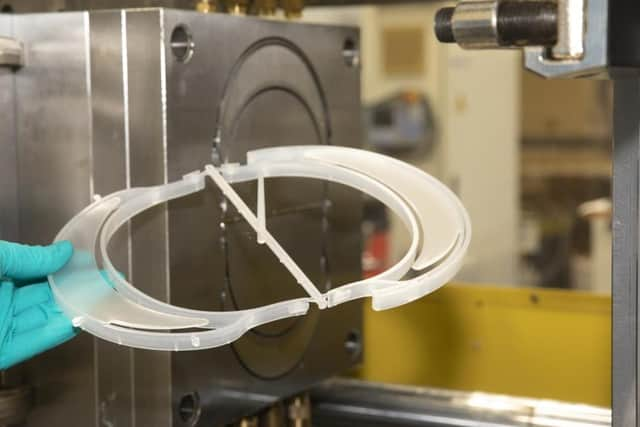

"We are manufacturing headbands and headpieces to go around the head, which you can then attach a visor to."

Professor Gough said it had taken a number of weeks to get to the point of manufacture.

Advertisement

Hide AdAdvertisement

Hide Ad"It has taken us some time to get to this stage because everything has to comply with strict cleanliness standards, so we have had to deep clean everything, even the injection screws and screw barrels, to create a clean room environment," he said.

The team is using high tech 3D printing and polymer injection moulding machines, capable of turning out thousands of pieces of protective face shield components a day.

Chris Wray, ActiveCell Technologies managing director, added: "We managed to scale our print farm up quickly to keep up with demand.

"To help create a design that is not only fit for purpose but helps protect the frontline workers in the NHS, private sector and care homes makes us extremely proud.”

Advertisement

Hide AdAdvertisement

Hide AdMould sets ordered from Germany and designed and machined in Bradford mean the university has the capacity to produce in excess of 5,000 units per day if needed.

The initial NHS order was for 10,000 units, with a further 5,000 ordered by Bradford Council.

Prof Ben Whiteside, who is part of the six-strong team from the university, said: "The challenge has been to review the problem, finalise designs and manufacture tooling at time scales that are far quicker than industry norms, while also offering significant benefits over existing solutions for our NHS staff."

The team are also working on two other designs, one called an ‘ear saver’ to stop chafing caused by prolonged mask wearing in a medical setting and an alternative face shield design for use in care homes.

Advertisement

Hide AdAdvertisement

Hide AdProfessor Gough is part of a six-strong team, which also includes Professor Whiteside, who leads the Polymer Micro and Nano Technology Research Centre, and research engineer Michael Hebda, technical services manager David Barker and engineers John Hornby and Glen Thompson.

Join our new coronavirus Facebook group for the latest confirmed news and advice as soon as we get it________________________________

Editor’s note: first and foremost - and rarely have I written down these words with more sincerity - I hope this finds you well.

Almost certainly you are here because you value the quality and the integrity of the journalism produced by The Yorkshire Post’s journalists - almost all of which live alongside you in Yorkshire, spending the wages they earn with Yorkshire businesses - who last year took this title to the industry watchdog’s Most Trusted Newspaper in Britain accolade.

Advertisement

Hide AdAdvertisement

Hide AdAnd that is why I must make an urgent request of you: as advertising revenue declines, your support becomes evermore crucial to the maintenance of the journalistic standards expected of The Yorkshire Post. If you can, safely, please buy a paper or take up a subscription. We want to continue to make you proud of Yorkshire’s National Newspaper but we are going to need your help.

Postal subscription copies can be ordered by calling 0330 4030066 or by emailing [email protected]. Vouchers, to be exchanged at retail sales outlets - our newsagents need you, too - can be subscribed to by contacting subscriptions on 0330 1235950 or by visiting www.localsubsplus.co.uk where you should select The Yorkshire Post from the list of titles available.

If you want to help right now, download our tablet app from the App / Play Stores. Every contribution you make helps to provide this county with the best regional journalism in the country.

Sincerely. Thank you.

James Mitchinson